Water Underfloor Heating Floor Constructions

View the various floor construction set ups for installing water based underfloor heating.

Solid / Screed floors

Screed on Insulation - Insulated Over Slab

Screed on insulation is the most common method of fitting UFH. It can be used for new builds, and renovations with an existing slab where the final floor height can be raised.

Screed on Insulation is one of the most common methods of installing under floor heating. It can be used for new builds, and renovations with an existing slab where the final floor height can be raised.

The pipe is held in place using barbed pipe staples (supplied), which push into the insulation, or tied to a lightweight mesh (such as D49 or A142) which is simply loose laid on the insulation. Pipe spacing is generally 100mm from perimeter walls and 250mm centre.

Beam and Block

Beam and Block floors are ideal for the installation of UFH. Their greater usage for intermediate floors in Europe (rather than wooden joists) has helped to establish UFH.

Beam and Block floors are ideal for the installation of under floor heating, and their greater usage for intermediate floors in Europe (rather than wooden joists) has helped to establish under floor heating.

For a new build, the use of beam and block in place of joists simplifies and speeds up the installation process. The pipe is held in place using barbed staples (supplied), which push into the insulation, or tied to a lightweight mesh ( such as D49 or A142) which is simply loose laid on the insulation. Pipe spacing is generally 100mm from perimeter walls and 250mm centre.

Insulated Under Slab

Insulation Under Slab is becoming more common. By insulating below, the slab becomes part of the thermal mass of the property.

This type of floor is generally considered to be more energy efficient, whether you are heating the property with radiators or UFH.

A key point to note is that the insulation needs to be of sufficient density to take the weight above. The pipe is either secured to the slab using pipe clips or tied to a lightweight reinforcing mesh (D49 or similar) which is loose laid across the slab. Pipe spacing is generally 100mm from perimeters and 250mm centres.

Single Pour Slab

Single Pour Slab is commonly used in industrial applications. The pipe is tied to loose laid reinforcing mesh, which is then raised and supported prior to the concrete pour.

The pipe is tied to loose laid reinforcing mesh, which is then raised and supported prior to the concrete pour. The surface of the concrete is then power floated. This construction method provides a large thermal mass which acts as a heat store. It can also be successfully used for domestic applications. Pipe spacing is generally 100mm from perimeters and 250mm centres.

Joist / First floors

Between joists is commonly used in renovations where the floor level cannot be increased.

Dry sand cement method

Each joist needs to be notched at one end within 120mm of the perimeter wall to allow the pipe to pass through. The pipe is held in place using the supplied pipe staples. Pipe spacing is generally 100mm from perimeters and 200mm centres. The additional weight is generally within the joist capacity, but if you are unsure, please

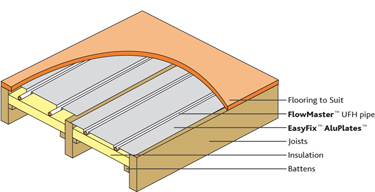

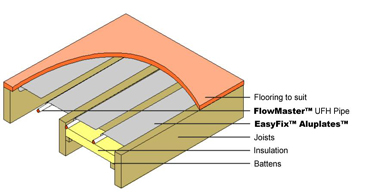

Aluplate Fit from above method

Aluplate Fit from below method

Over Joist

Over joist is commonly used in new builds, or in renovation where the floor level can be raised.

The pipe is held in place using the supplied pipe clips. Pipe spacing is generally 100mm from perimeters and 200mm centres. The additional weight is generally within the joist capacity, but if you are unsure,

Floating Floor

Battened Floor

Battened floor construction is typically used in an existing property when a solid wood floor is required (although this can be laid to other constructions simply). Its key feature is that it uses the dry mix as the thermal mass around the pipes, rather than a structural screed, and the increase in floor level is minimal.

It is also possible to substitute the 50 x 50mm battens for 25 x 25mm battens, using thin insulation (typically 8mm), and then infill with dry mix. This method however is not considered to be adequately insulated but it does allow an even smaller increase in floor height and may be suitable if your floor is already insulated in a lower layer.